Sale!

Produkt information

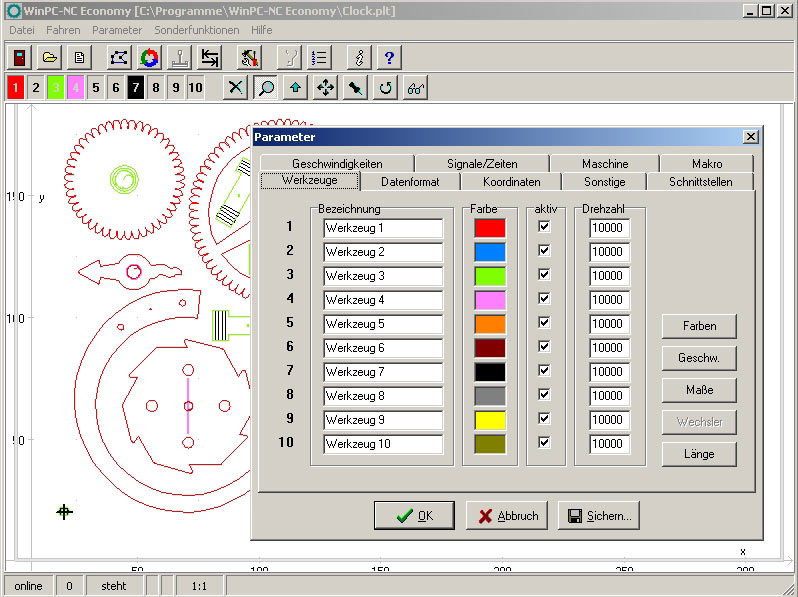

Our well-known and well proven CNC control program WinPC-NC is available from version 2 in three different versions:Light / Economy / Professional

WinPC-professional

The available for several years WinPC-variation with external axis controller CPU also meets all requirements for industrial applications and is the outsourcing of all time-critical real-time functions on the axis controller is absolutely stable, reproducible and installed by system conditions, or other, or in the background running programs completely independent .

WinPC-for over 6 years around the world hundreds of times every day proves successful operation and its reliability and accuracy in various applications.

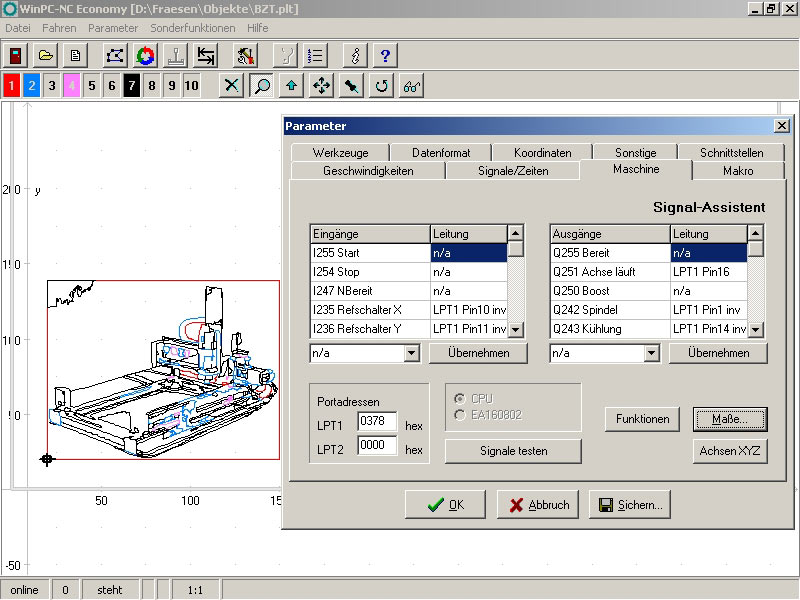

The included axis controller is available in various configurations and with optional adapters, signal, or other external Eingangs-/Ausgangsmodulen keypad for easy machine setup. It is connected with a serial cable to connect your Windows PC or connected to a USB-serial + adapter and then does its control tasks reliably and completely self-sufficient.

Technology functions

WinPC-owns in conjunction with the axis controller CNCCON some technological features that enable the control of external components or besonderren are needed for various specialized tasks. Here you will find a general overview.

Dose

WinPC-specific controls a digital output for the metering pump and uses a defined start time and post-travel, ie switches the pump already has a certain distance before the end of contours, to prevent dripping.

Double X-axis and orientation in homing

The drive of large and heavy bridges can be made with two parallel motors, which are always controlled synchronously. When homing is achieved using a special function and two reference switch the exact perpendicular alignment.

Storage on the axis controller and operating without a PC

Work processes and jobs up to 10 Megabytes of size can be stored directly on the axis controller and is then repeated without a connected Windows PC for serial production.

Coupled opto outputs (24V)

As an option, can be operated up to 48 opto-isolated inputs and up to 24 Optoentkoppler or relay outputs with our axis controller. Thus, the use in industrial environments is ensured.

Soft-PLC

In the axis CNCCON a complete integrated software PLC. They may be similar to Step-5 with over 50 PLC commands (flags, counters, timers, etc.) programmed. This allows various safety functions, control of peripheral devices and complex monitoring functions in parallel to realize the CNC tasks.

Analog output 0-10V for spindle speed

The spindle speed of conventional inverters can be controlled with a 0-10V signal output. Furthermore, the synchronization of the sequence with an input spindle speed is achieved and possible additional inputs such as spindles and spindle stop errors are monitored.

Speed and speed override

Both the feed rate and spindle speed can be changed online during the movement by pressing a key on the keypad or mouse click immediately between 10% and 200%.

Z-Clipping

When defining a maximum digging depth WinPC-NC monitor these and all subsequent crop piercing in 3D jobs at this limit. Thus, for example the table surface to be protected from accidental damage.

Monitoring inputs with various error messages

The monitoring of different input errors, such as light curtains, protective hood, fill height of spray cooling, compressed air, ready to drive and can be monitored more easily and view the results with user-definable messages.

Ramp loadable profiles

CNCCON automatically calculated by the ramps have a slight sinusoidal profile and are thus well suited for most applications. With the use of unusual or unfavorable kinematics of the axles, other loading conditions, supply rechargeable ramp profiles are often a better acceleration performance. The ramp sections are available as text and tables are selected by parameter.

Synchronization with various input signals

The execution of a CNC program can WinPC-NC synchronize with various input signals. Possible, for example, are an external start signal, a signal clamping firm and the use of non motorized Z-axis for two signal Z and Z above the bottom.

Individual Macros

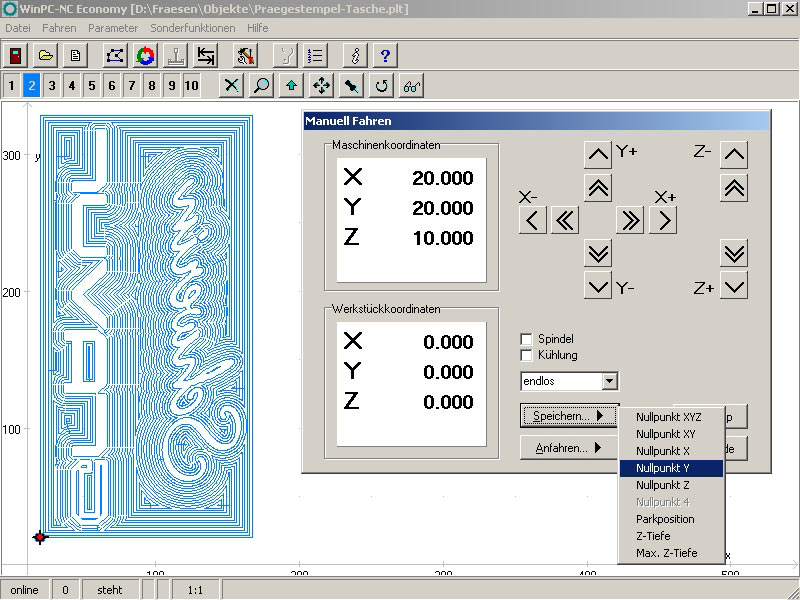

One of the strongest features of WinPC-NC is the liberal programming macros. Here, let sit several functions such as vehicle movements, waiting, waiting for inputs, outputs reset / etc together and bind to specific program situations. Macros can e.g. on job start and end are executed before and after Z-motion (PU and PD commands), when changing tools and other states. Application examples are the insertion procedure when cutting or controlling an automatic tool changer.

Block surface

Determine the starting and the workpiece surface or the machine table is done automatically WinPC-NC using a surface block. The thickness of the block is defined by parameters and will be deducted when calculating the Z-heights.

Automatic tool changer

With WinPC-is the control of automatic tool changers is a breeze. The individual and stacking Aufnehmvorgänge can comfortably controlled with macros and are thus adapted to various mechanisms. The synchronization is established with multiple digital signals, such as to stop spindle, collet press / tool. Also checking of tools in magazine positions is possible with digital signals and prevents malfunctions in the automatic switch.