Sale!

Produkt information

Our well-known and well proven CNC control program WinPC-NC is available from version 2 in three different versions:WinPC-NC Economy / Economy / Professional

The program WinPC-NC is a software that turns any standard personal computer makes a universal NC control and 3 - or 4-axis controls. Different versions with graded functionality and offer prices for both beginners and modelers, as well as for semi-professional use or for demanding industrial facilities the right solution.

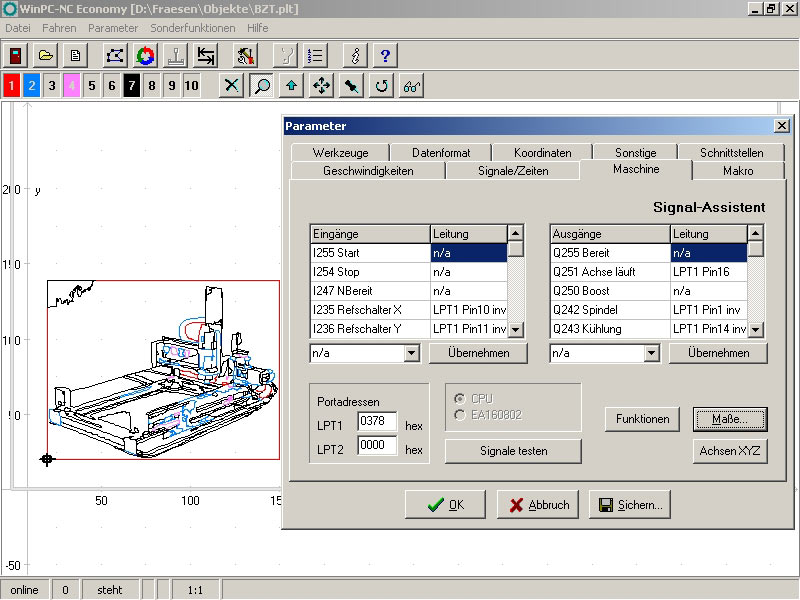

The WinPC-NC Economy controls connected machines or drives directly over existing LPT printer interface, with either clock / direction signals are used or SMC signals for widespread SMC800 or SMC1500 stepper motor cards.

Easy commissioning

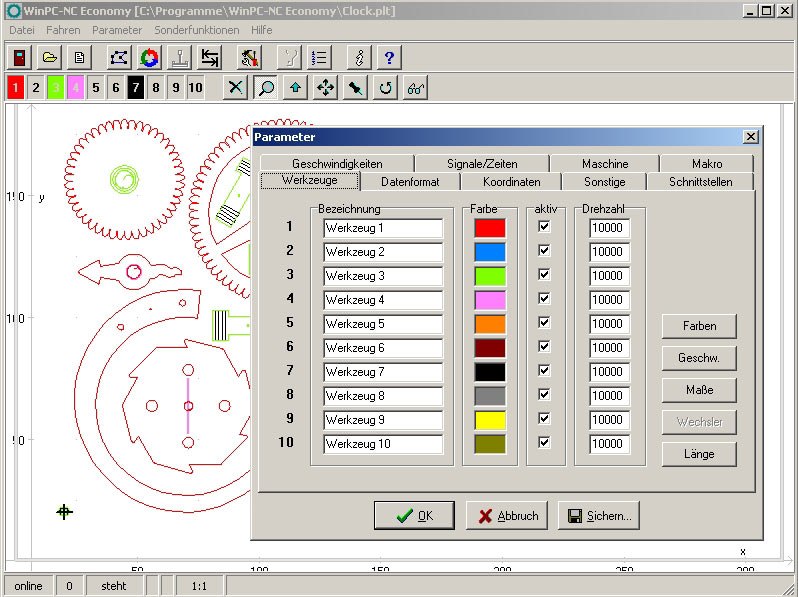

WinPC-NC is shipped pre-configured and can be operated without major problems. An easy to understand step-by-step instructions can be found in the attached manual or PDF manual on the CD. In addition to the standard motor signals, the use of various additional signals as additional inputs or outputs is possible. The definition and assignment of the signals are comfortable with the integrated signal Wizard. Determining the best axis parameters with the help of the tuning functions a breeze.

By many test functions and the detailed description is also the conversion of nonexistent machines or from other control programs easy to make. Upgrades of our old programs PC and PC-NC-NC SMC, we naturally offer at a discount.

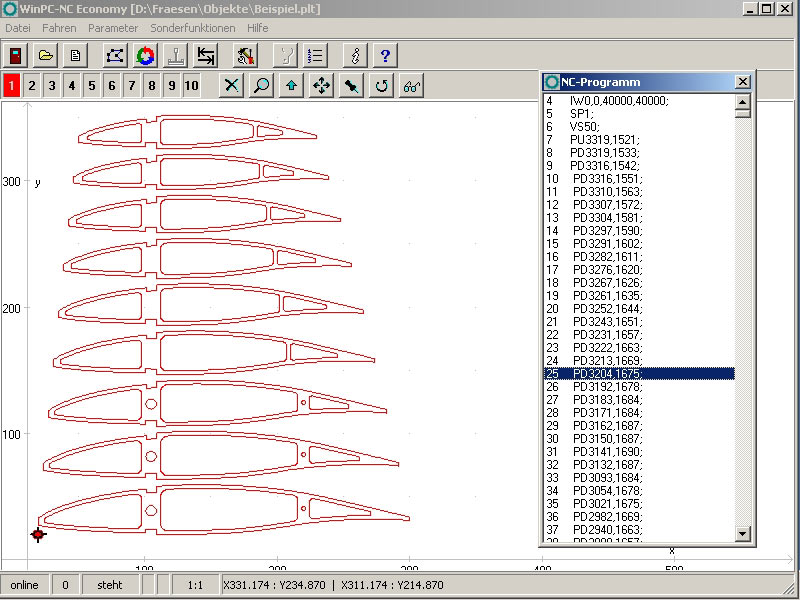

Import filters for multiple formats NC

WinPC-NC Economy has import filters for the widespread HPGL plotter language (PLT) and continuous drilling formats and making it ideal for engraving, drilling and milling of platinum 2D or 2.5D model components. In addition, other import filters for multicam files in 2D and 3D, for the DIN / ISO language, which is used in professional machines and further understands and ISEL-NCP programs and the vector information from EPS or AI files. You can either create new programs with the built-in editor itself, or with a program running under Windows character design (eg CorelDraw).

Light machine operation

WinPC-NC offers various functions and secure full control of the connected machine. The manual is step down just above the keyboard, mouse or joystick button. On various test functions can be optimized to perform to the parameters or check the Achseingänge defined.

WIN PC-NC true multitasking

WinPC-NC is a true multi-tasking program, and never blocked the operation of Windows or other programs. After starting a job driving on the machine you can easily switch to other applications, eg into a CAD program to design the next part. The quality of real-time control of motors and machines, but installed system of environmental influences, from the PC hardware and other programs running in the background and may be affected. In addition, the used PC system clock have at least 1 GHz and an operating system Windows XP or 2000.

Intelligent path control

WinPC-NC is a real path control, determined by the efficient look-ahead capabilities in all situations and sets the optimal speed. The machine moves during a motion task with the best possible constant speed, needs no "pauses" and fits perfectly to the handling always follow the contour. The train control system works reliably even if the inexact set are different for all axes or the engines have different driving characteristics.

WinPC-NC Economy at a Glance:

- simple, intuitive operation

- runs on PCs with 1GHz and Windows2000/XP

- Ramp and axis parameters individually adjustable

- interpolated move all axes

- Machine moves 2D, 2.5D and 3D real economy version also

- Import filter for HPGL, well data, 2D/3D multicam, DIN / ISO, ISEL-NCP and EPS / AI

- powerful integrated editor

- full multitasking capability, i.e., Start the machine and for example continue drawing in the CAD

- exact steps manual driving with keys, mouse and joystick

- graphical display with scale, zoom function, range switching

- various external signals for synchronization with other components

- Tool length measurement and compensation

- convenient production advantage

- Next Stop and run jobs without loss of position

- languages, other languages can be retrofitted

- comprehensive manual